Hard Tooling Sheet Metal

In the ideal.

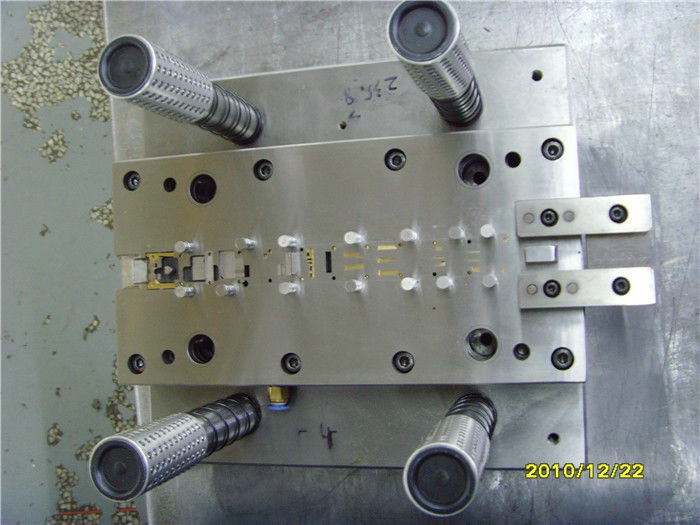

Hard tooling sheet metal. Hard tooling steel aluminum tools are used for the injection molding process for prototype or bridge but these tools are mostly used for high volume production 100 s 100 000 s. Sheet metal forming hammers also known as body and fender tools these hammers are excellent for forming and repairing dents in sheet metal components. Hard tools are tools made of metals. Many engineers developing 3d models for sheet metal products are unaware of the fabrication tools used to form the part or product and instead design models for an ideal world.

Figure 7 shows small steel parts being cut out of thinner sheet metal. Hard tools have to be made by third party vendors who specialize in such materials because they require precise machining and polishing. Stamping is a process using dedicated tooling mounted in mechanical or hydraulic presses to make sheet metal parts. That is a production rate of 4 pc.

Hard tool requires more procedure and longer time to manufacture. The key to a good hard tool is the surface finish. Soft tooling and hard tooling. The common operations associated with sheett maetal are blanking piercing and forming.

These air powered tools remove dents smooth out ridges and shape sheet metal more efficiently than manual hammers. Per minute or 240 per hour vs. Steel aluminum tools typically range in price from thousands to tens of thousands of dollars. The 900 per hour the hard tool produces.

This is also known as sheet metal bending sheet metal punching or sheet metal forming. Metal working tools include a wide range of layout tools. Difference between soft tool and hard tool soft tool. Trick tools offers high performance metal fabrication equipment and metal working tools like tube benders notchers saws english wheels and sheet metal brakes.

Industrial tool eckold mittler brothers beverly tennsmith sykes pickavant baileigh dotco ir desoutter and sioux. Industrial manufactures sheet metal tool and equipment and distributes products from other manufactures. There are two main sheet metal manufacturing processes. Hard tool is a high quality tooling for mass production it s made of the best quality steel like h13 420 etc.

Further adding to the cost difference are the expenses for consumable such as gases required for the plasma table s production. Soft tooling uses lasers turrets and brake presses to form parts and components through cutting punching and bending.

.png)