Hfi Sheet Metal

Current estimates show this company has an annual revenue of 10661136 and employs a staff of approximately 30.

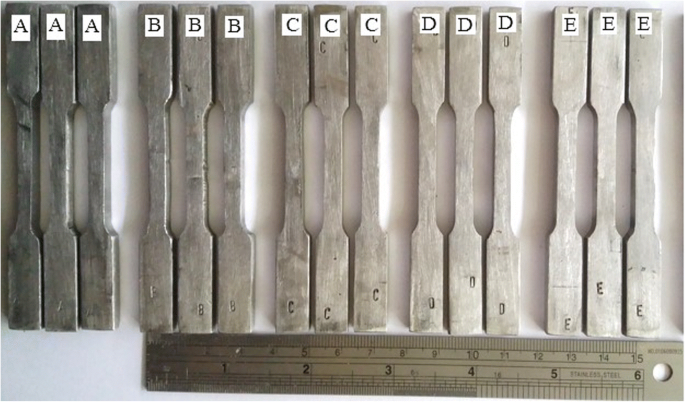

Hfi sheet metal. The above chart provides a quick way to make a pre selection of material type. In the saw welding process external filler metal wire electrodes are used to join the formed plates. For a more detailed assessment please refer to each material data sheet or contact us. Sheet metal and air conditioning contractors national association smacna chantilly va associate member program product show.

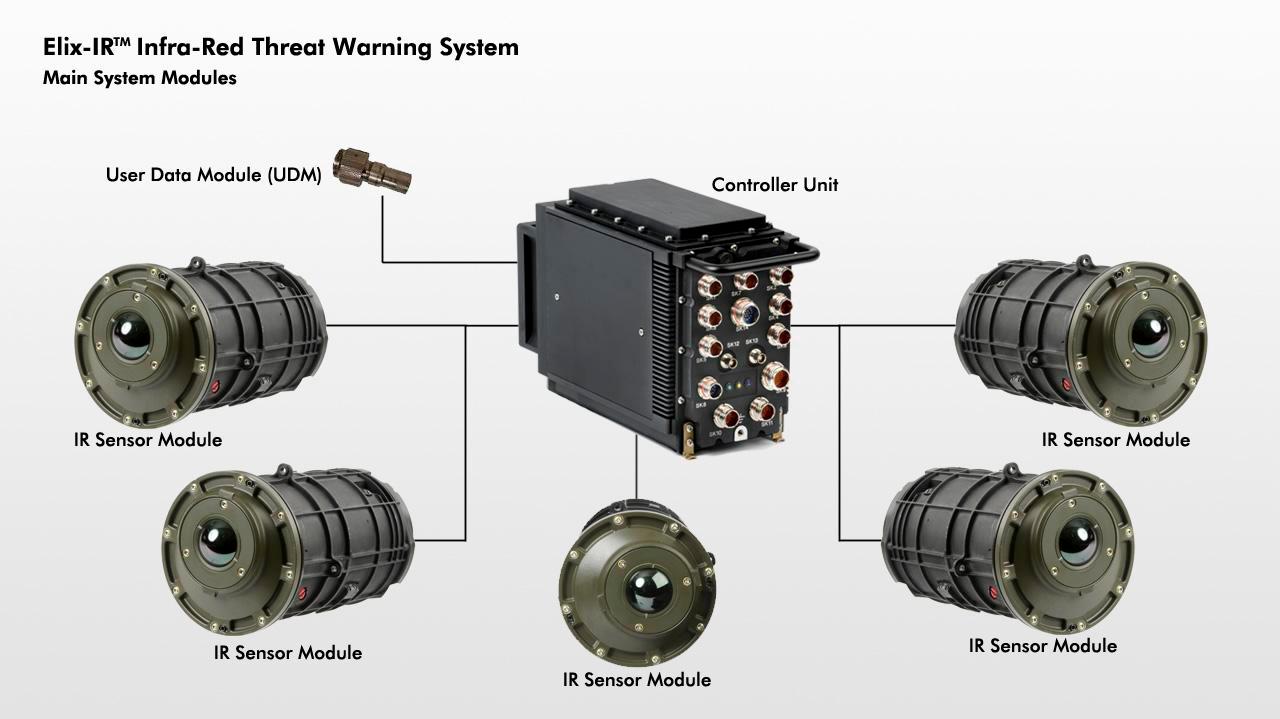

The endless strip passes through rolling stands where it is shaped to an open pipe which runs through a high frequency inductor consisting of a metal coil with single or multiple windings. 812 424 3681 email local 20 of evansville. It should be used as a guideline. Saw pipes are also available in the spiral seam which is continually rolled from the single plate coil.

Hfi is a full service sheet metal fabricator specializing in stainless steel innovation for fifty years. Built on strong japanese values amada offer a wide range of innovative solutions in fibre laser press brakes punching welding automation and combination machines. Our records show it was established in 1967 and incorporated in il. Sheet metal worker s local 20 1301 west franklin street evansville in 47720 phone.

Hfi sheet metal stainless steel fabrication. Reliable and optimized material selection depends upon a large set of parameters from fluid characteristics to well conditions. We specialize in stainless steel manufacturing and are a full service metal fabricator with a nearly 60 000 sq. Amada is a world leading manufacturer of comprehensive sheet metal machinery.

Categorized under sheet metal fabricators. Hfi welding mannesmann line pipe uses the high frequency induction hfi resistance pressure welding technique for longitudinal welding. Founded in 1967and based in west chicago ill howler fabrication welding specializes in metal fabrication welding and metal finishing. Our solutions also include software packages tooling and original spare parts.

Our 63 000 square foot facility is home to the latest and most updated fabrication and welding equipment built to service the restaurant medical telecommunications display and other sheet metal markets. Hfi clearly respects the fiduciary relationship that we have developed with several clients over the years. The company is supplier of high quality sheet metal components and assemblies and on time delivery.